|

|

Extruding Ice from Pipes - Winter 07-08 by Dr. James R. Carter, Professor Emeritus Geography-Geology Department Illinois State University, Normal, IL 61790

|

|

|

|

In

fall 2004 I became fascinated with ice

formations that occur on selected plant species and have been conducting

many experiments since then. In January 2007 I was introduced to some

beautiful photos of ice

growing as ribbons and rods from a metal fence. For the rest of

that winter I explored forming and growing ice

trying to replicate those exotic ice formations. I made some progress.

Over the summer I tried to grow ice in freezers wherever I could find

them. I had limited success. Then in winter 2007-08 I had

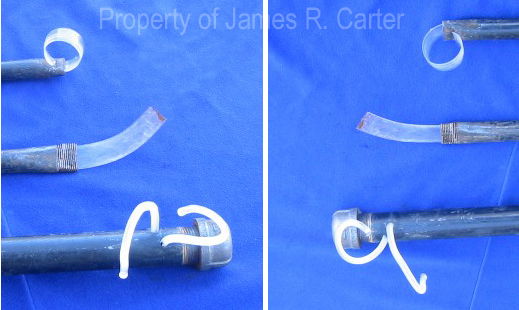

greater success, as shown here. In my first year I learned plastic and cast-iron pipes were not strong enough to stand up to ice, but black steel pipes did the job. My favorite tool has become a 36 inch (90 cm) black steel pipe, 1/2 inch (1.25 cm) in diameter. The two images below show extrusions of ice from different pipes of these dimensions. In the images above my wife is holding the pipes. The red tint is rust from the pipe. After getting similar images regularly I made small modifications to the outlets of the pipes. Below is another set of extrusions of ice from the same two pipes, although the pipes are switched left to right above and below.

Ice will expand in volume by about 10%. So, the longer the pipe the more water can be extruded to form ribbons or rods of ice. In the pair of mirrored images below I have three sizes of pipe. The small loop at the top is from a 12-inch pipe, 1/2 inch in diameter. This thin loop is all that could be gotten from this volume of water. The pipe in the middle is the 36-inch pipe but for some reason it did not produce the longer ribbon this time. But this ribbon is appreciably thicker than the thin loop from the shorter pipe.

At the bottom are two rods of ice extruding from a 36-inch pipe 1.0 inch in diameter. That pipe of twice the diameter holds 4 times of volume to water as its narrower partner. In this wider pipe I drilled two holes 1/4 inch in diameter. The two rods of ice are the product of this experiment. I have found it quite difficult to get photos that show the ice formations distinct from the background noise. Some of the best photos are held against a dark color coat or placed on a plain color surface. The large blue cloth seems to provide a nice background for this ice. Below are two perspectives on the same ice formation from one of the 36-inch pipes, 1/2 inch in diameter. I inserted a screwdriver into the end of the pipe and applied a couple of tweaks and this is the pattern of ice I got. And, I have duplicated this type of ice formation on subsequent attempts from this pipe.

On the fence in British Columbia there were two long rods of ice that extended up from the base of the fence. My experiment with the two holes in the 36-inch pipe were an attempt to replicate that ice formed on the fence. Below are two examples of ice being extruded as rods. Remember, this is a pipe 1.0 inch (2.5 cm) in diameter. The example on the left is the longest extrusion of ice I was able to get. It is quite smooth and of uniform texture.

By contrast the extrusions of ice on the right show fractures as if the ice emerged from the pipe in halting steps. This photo was taken at night with a flash, which is why you see the shadows. Ten minutes after taking this photo we heard a large bang as the ice rods shattered. It proved difficult to grow ice as cylindrical rods and keep them. But I did demonstrate that it can be done and it does replicate to my satisfaction what was found on the fence. I think the temperature is an important factor in the nature of the ice that can be grown. I would like to be able to duplicate a number of experiments in a controlled environment where I could work at fixed temperatures and make observations about the resulting ice formations. But I am limited to what nature gives me and so I cannot control temperatures. So, some days it is colder than I want and on other days it is not cold enough. Such is life. I invite others to try their hand at extruding ice from pipes, or steel fences, to see what you can come up with. If it were easier to keep the ice formations, we could have national and international ice extrusion meets. All you need are some cold days and places to get warm to thaw the pipes and get fresh water. After considerable experimentation I found all that you need is below on the left, plus freezing temperatures. Get a black steel pipe and flatten one end, somehow. Then seal off the flattened end with a plastic bag and a couple of rubber bands. Add only enough water to form a block of ice at the bottom of the pipe. I add about 5 cc of water to a 12 inch pipe and about 15 cc of water to a 36 inch pipe. I want to keep as much open space in the pipe for the additional water that will expand and push the plug of ice out the end. I then stand the pipe vertical outside in freezing temperatures. If it is snowing, I will cover the open end.

After a few hours when I am think the ice is frozen at the bottom of the pipe I fill the pipe and cap it off. But I want to make certain the water I add to the pipe does not melt the ice already in the pipe. So, I place water in plastic bottles and set them outside to freeze. When I have ice in the plastic bottles, but they are not yet frozen solid, I pour that water into my pipes. Then I cap off the pipes. But make certain the caps are above freezing. If not, water will immediately freeze on a cold cap, and you will have a frozen mess and probably cannot screw the cap on. And, I have filled my caps with Goop so there is less room for expansion of ice into the cap. Then, take off the plastic bag and rubber bands and put the pipe where you want the ice to grow. I usually lay the pipes down and raise the capped end slightly, so any air bubble stays at the capped end. Come back in a few hours and ‘Enjoy’. However, everything will not go as planned. In the photos above you can see some problems. There are two cast iron caps that have been shattered by the expansion of the ice. The piece of pipe is one of my 36-inch pipes. Note how the pipe has been pushed out in the threaded portion, below the cap. That bulge ripped the metal. This year that pipe will be used as a garden stake. The broken coupling on the right came from my attempt to go from a ¾-inch pipe into a ½-inch pipe. I was trying this in a refrigerator where I could use only short pieces of pipe. Breaking that cast iron coupling was easier than extruding ice out of the end of the pipe. So, how do these experiments relate to the ice formations on the fence? I argue that in the case of the fence, rainwater seeps into the fence and puddles up, to great depths in some places. On some nights the water freezes. The next day some of that ice melts, but not all. The ice that remains in the fence floats on top of any water. In some places that ice becomes trapped against the upper surface of the fence. Then the next time the water freezes it expands and pushes against the floating ice. Where there are openings in the fence the ice is extruded through those openings to create some very interesting ice formations. Thankfully, Sheryl was there with her camera and presence of mind to capture those ice formations on her fence for our pleasure. I suspect such ice formations in nature are quite rare. Now I invite others to see how they can build on this process to create interesting ice formations by extruding ice through pipes. With the power of the Internet, I hope to see some other examples. For those of you who live with cold temperatures take advantage of those cold temperatures. I am not certain this tells us anything about the ice flowers and ice ribbons that grow on selected species of plants but it is a nice diversion when I cannot see ice growing on plants. |

|

|

|

One of a number of pages on Ice Flowers and Ice Ribbons by Jim Carter. To go to my master web page. Email: jrcarter@ilstu.edu |

|